Modern Living Pro

Wood Grain

PR401 North Haven

$2.79 per sqft.

PR402 Saratoga

$2.79 per sqft.

PR403 Sorrento

$2.79 per sqft.

PR404 Beulah Valley

$2.79 per sqft.

PR405 Dream Lake

$2.79 per sqft.

PR406 Pikes Peak

$2.79 per sqft.

PR407 Maroon Lake

$2.79 per sqft.

PR408 Pleasant Hill

$2.79 per sqft.

PR409 Rising Sun

$2.79 per sqft.

PR410 Paradise Bay

$2.79 per sqft.

PR411 Sunrise Meadow

$2.79 per sqft.

PR412 Golden Meadow

$2.79 per sqft.

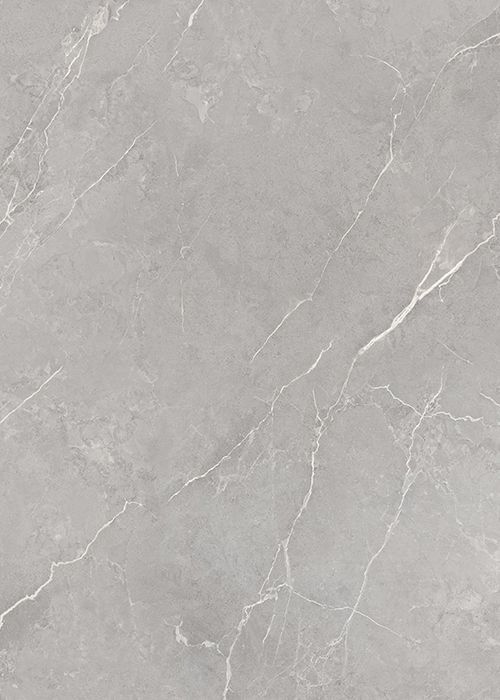

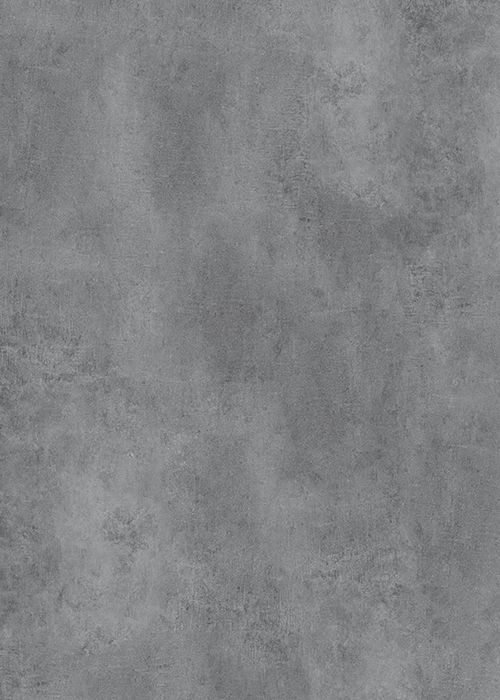

Stone Grain

PR421 Rock River

$2.79 per sqft.

PR422 West Cliffe

$2.79 per sqft.

PR423 Gray Mountain

$2.79 per sqft.

PR424 Glacier Gorge

$2.79 per sqft.

Modern Living Rigid Core Pro

Rigid Core Pro collection presents most authentic wood plank and stone tile look and texture with high-definition imagery plus and Embossed In Register technology. Various luxurious wood and tile designs with realistic HD-3D printing technology and painted bevel enhanced its gorgeous aesthetic. Ultra-fresh treatment for both attached underlayment and top surface inhibits the growth of mold, mildew and odor even with moisture from concrete subfloors.

Comfortable to daily life, friendly to pets!

Waterproof

ScratchGuard Finish

Suitable for Commercial Use

Pad Attached

INDUSTRY-LEADING RESISTANCE

TO SCRATCHES, STAINS, AND DENTS

Bolstered by the strength of real diamonds,

protected by the Wear Layer,

protecting the beauty of your investment.

Wood Grain Specifications

Length

48.03"

Width

7.16"

Thickness

5.5mm

Wear Layer

20mil

Finish

EIR

Edge Description

Painted Bevel

Sqft/Box

23.90

lb/Box

41.1

Box/Plt

65

Sqft/Plt

1554

lb/Plt

2673

Plt/20'FCL

20

Limited

Residential Warranty

Lifetime

Limited

Commercial Warranty

15 Years

Stone Grain Specifications

Length

24"

Width

12"

Thickness

5.5mm

Wear Layer

20mil

Finish

Tavertine

Edge Description

Painted Bevel

Sqft/Box

24.00

lb/Box

41.3

Box/Plt

66

Sqft/Plt

1584

lb/Plt

2725

Plt/20'FCL

20

Limited

Residential Warranty

Lifetime

Limited

Commercial Warranty

15 Years

Technical Data

| Items | Standards | Requirements | Results |

|---|---|---|---|

| GreenGuard Gold Certified | UL 2818 - 2013 Gold Standard for Chemical Emissions for Building Materials, Finishes and Furnishings | Refer to Standards | Pass |

| Floorscore Certification | SCS-EC10.3-2014v3.0 | Refer to Standards | Pass |

| CE Certification | EN14041 | Refer to Standards | Pass |

| Fire resistance | EN 9239-1 EN ISO11925-2 EN 13501-1 | Critical Fluxf≥8.0kW/m2 Fs≤150mm within 20s Smoke≤750% minutes | Bfl-S1 |

| Phthalate tests (DBP/BBP/DEHP/DINP/ DNOP/DIDP) | EN 14372:2004 | N/A | Free |

| Dimension stability | ASTM F2199-09(R2014) | ≦0.25% | Manufacturing direction:-0.046% Across-manufacturing direction:-0.009% |

| Seam strength | EN 684:1995 | N/A | Ave.:360N/50mm Pass Min.:330N/50mm |

| Residual indentation (%) | ASTM F1700-13a & ASTM F1914-07(2011) | Average value≦8 Individual value≦10 | 0.4 Pass |

| Resistance to chemicals | ASTM F1700-13a & ASTM F925-13 | No more than a slight change in surface dulling,surface attack,or staining | No change in surface dulling,surface attack,or staining was detected |

| Heat stability | ASTM F1514-03(R2013) | △E*ab< 8 | △E*ab=0.67 Pass |

| Static loading | ASTM F970-17 | N/A | 0.04mm Pass |

| Soluble heavy metal contents test | ASTM F963-16(Clause 8.3) | N/A | Free |

| Large ball impact resistance | NALFA/ANSI LF-01-2011 | N/A | No cracks or fractures occurred at the height of 2500mm |

| Static Electrical Propensity | EN 1815:2016 method A | ≦2kV | 0.2kV |

| Sound Transmission Class | ASTM E90-2009(R2016) ASTM E413-10 | N/A | STC=68 |

| Formaldehyde | ISO 17226-1:2008 | N/A | Free |

| Surface Bond | NALFA/ANSI LF-01-2011 | N/A | 1.14MPa Pass |

| Resilient floor covering Determination of peel resistance | EN ISO 24345:2012 | ≥54N/50mm | Longitudinal direction:95N/50mm Cross direction:95N/50mm |

| Castor chair Resistance(25000 Cycles) | NALFA/ANSI LF-01-2011 ISO4918:2016 | N/A | No damage was found after test |

| Thermal conductivity | EN 12667:2001 | N/A | 0.154 W/(m.K) |

| Thermal Resistance | EN 12667:2001 | N/A | 0.033(m2.K)/W |

| Color Fastness | EN ISO 105-B02:2014 | N/A | Grade 6 |

| Curling | ISO 23999:2008 | N/A | Average: 0.5mm Pass |

| Locking strength | ISO 10582:2017 Annex D | Class 32, type I:≥1.5kN/m | Long side(X): 7.6 kN/m Short side(Y): 6.3 kN/m Pass |

| Resistance to staining | ISO 26987:2008 | N/A | Index 0: Not affected Pass |

| Slip resistance (oil-wet ramp test) | DIN 51130:2014-02 | N/A | Critical angle of inclination: 14.8°Classification: R10 Pass |

| Resistance to bacteria | ISO 846-1997 Method C | N/A | Assessment of bacteria growth: 0 Pass |

All Rights Reserved | Modern Living Flooring POWERED BY Isbill Tech Services